The ConviTec control is installed in a control cabinet or as a group in closed steel sheet design, make Rittal, and built and tested according to the applicable VDE-/IEC regulations. The main components of the control are components of well-known suppliers and correspond to the latest state-of-the-art. ConviTec offers you a comprehensive program of customized controls.

The machines are operated in automatic mode from the control room or in local mode using the touch panel on the cabinet door or in maintenance mode on the respective machine on site. To preselect the operating place use the preselection switch installed in the control cabinet door. The buttons and lights such as status lights, acknowledgement button and the main switch required for the local control are located in this door.

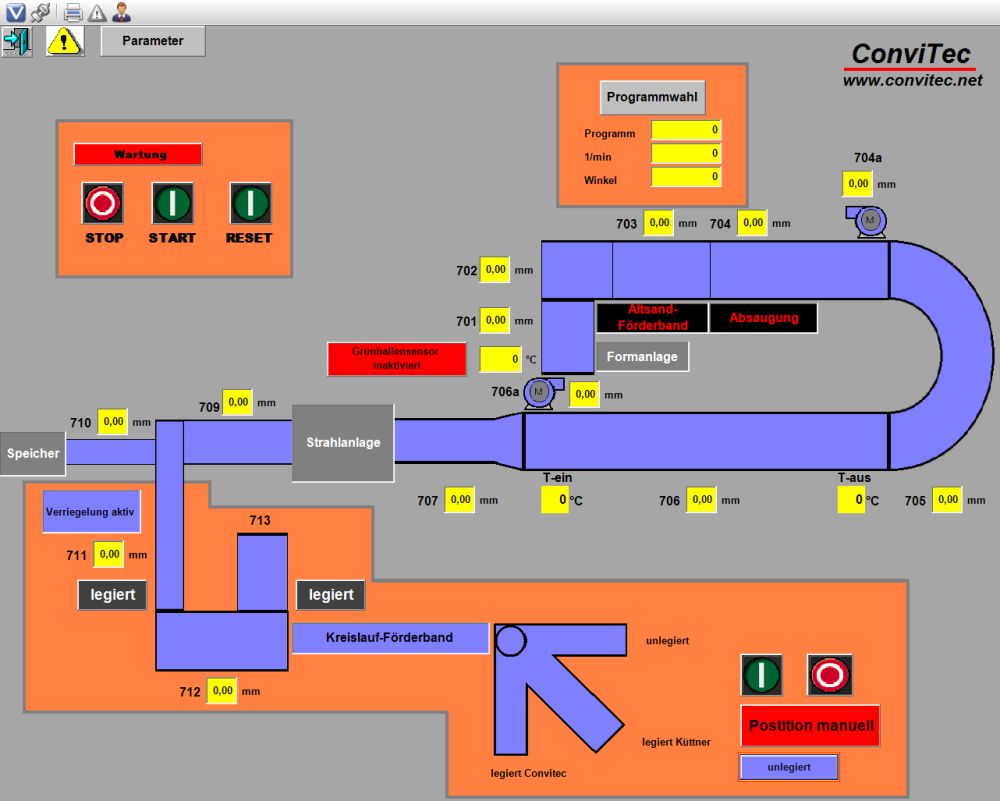

The entire plant is controlled, locked and monitored by means of a freely programmable control and a touch panel with graphical colored user interface.

The control computer can be allocated the following tasks as for example:

- Plant visualization including status display of the individual drives,

- Preselection and display of the shake-out index with a Vario feeder,

- Preselection and display of the casting program number,

- Display of the conveying speed with a casting cooler,

- Display of the air inflow and outflow temperature,

- Status display of the individual drives,

- Indication of the operating mode,

- Maintenance notes,

- Clear text message of plant errors, their acknowledgement and archiving,

- Communication with superior systems.

- Control cabinet

- PLC control

- Frequency converter

- Ethernet

- Profinet

- Profibus

- Visualization

- Touch Panel

- I-WIFI

- Bluetooth

- Vibration monitoring

- Operating data acquisition

- Measurement and regulating systems

- Weighing technology

- Online support

- Automatic mode

- Manual mode

- On-site operation

- Communication with superior systems

- Automatic plant operation

- Energy-efficient operating mode

- Appropriate for automatic operating data acquisition

- Network

- Remote maintenance

Are you interested in our control technology? Or do you have any further questions?

We look forward to your inquiry.

We look forward to your inquiry.