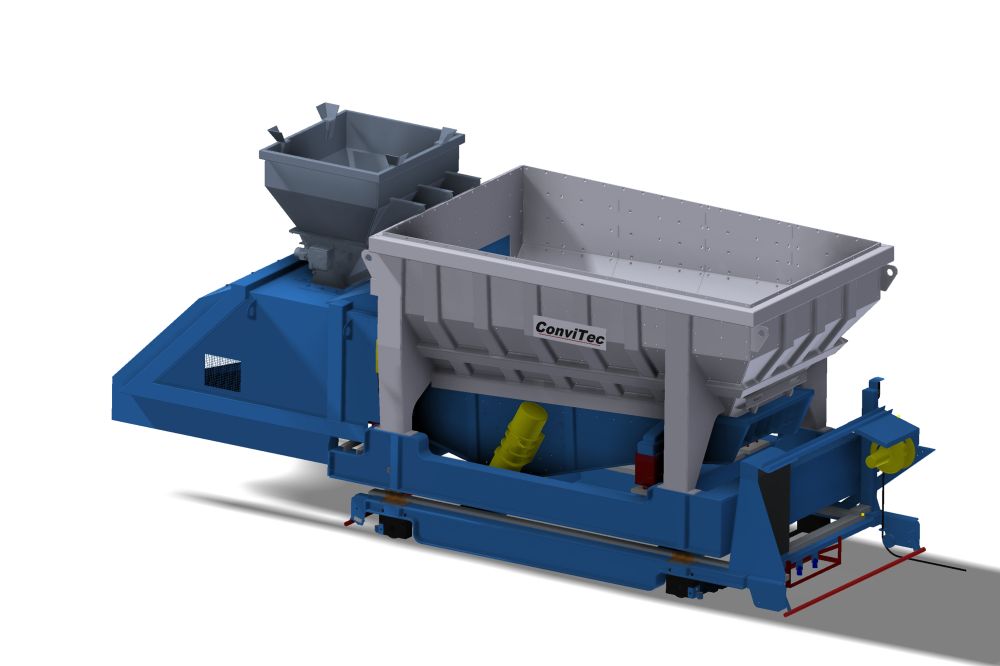

ConviTec furnace loaders COB are used for precise and gentle charging of melting furnaces in foundries. A vibrating conveyor with hopper and control cabinet, which are mounted on a drive frame, are the main assemblies. The furnace loaders are mostly moved lengthwise and can charge several furnaces through a transversal drive frame, if necessary. Filling is usually effected by means of a charging magnet or lifting-tilting device. ConviTec plans and delivers you complete furnace charging systems. Common charging goods include for example various scrap metals, scrap packages, chipped scraps, recycling materials, chips, granules and alloyed elements. The furnace loader is located on compression springs, isolated from vibration and usually driven by two unbalance motors. The conveyor trough can be designed as a sound-reducing sandwich type and with wear lining. The outlet consists of heat-resistant material and can be equipped with a pendulum cap on request.

A special sealing blanket fixed to the drive frame is used as sealing element between feeder and furnace opening and is adjusted to the respective requirements of the furnace. The flap, which can be operated electrically or manually, closes the hopper during filling in the charging place. It is possible to attach an additional container for aggregates. Weighing components can be integrated in the system for recording of the input materials. Optionally sound protection elements are installed in order to reduce the noise emission.

- Vibrating feeder

- Unbalance motors

- Hopper

- Manual/electric flap

- Bunker for additives/aggregates

- Electric bunker lock

- Drive frame (lengthwise/transversal)

- Sight glass

- Docking blanket

- Control cabinet

- PLC control

- Cable drum

- Safety devices

- Sensor system (vibration monitoring)

- Signal exchange

- Weighing technology

- Sound protection

- Transport through vibration

- Movable (lengthwise – transversal)

- Controllable with control bulb or via control panel

- Remote controlled with I-WIFI or Bluetooth

- Move automatically to certain positions (filling, maintenance)

- Communication with furnace control, rolling gates and charging units

- Energy efficient furnace charge due to automated process

- Gentle and therefore wear-reducing furnace charge

- Precise charge

- Minimizes emissions

- Occupational safety due to mechanic charge

In order to be able to process your inquiry more efficiently you will find a questionnaire here through which you can send us the most important information already in advance.

Are you interested in our furnace loaders? Or do you have any further questions?

We look forward to your inquiry.

We look forward to your inquiry.