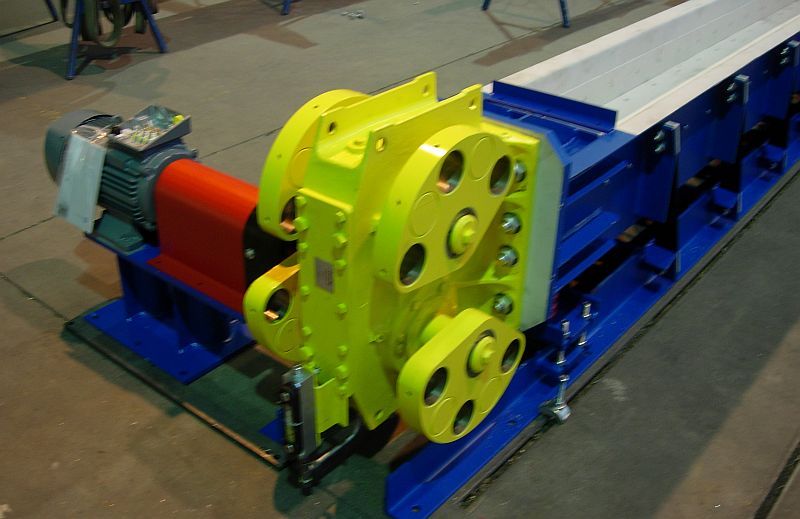

ConviTec Vibro conveyors CRF are used to transport bulk materials such as foundry sand, blasting materials or mineral raw materials. In this respect, as many feeding and discharge points as possible can be implemented. As to the structure the Vibro conveyor is designed as a two-mass system with conveyor troughs and wear lining. The drive unit of the Vibro conveyors is connected with the trough and consists of a three-phase motor, drive shaft and directed exciter or unbalance motors. A basic frame is directly connected with the foundation or steel structure and is used as second mass. Spring elements are placed between conveyor trough and basic frame for elastic support. The Vibro conveyor can also be designed as an isolated conveyor where the basic frame is placed on compression springs isolated from vibration.

- Vibrating conveyor

- Two-mass system

- Single mass system

- Drive shaft

- Drive motor

- Directed exciter

- Unbalance motors

- Frequency converter

- Trough

- Several inlets

- Several outlets

- Trailing arms

- Insulating frame

- Compression springs

- Firmly anchored

- Control cabinet

- PLC control

- Sensor system (vibration monitoring)

- Screen section

- Safety devices

- Transport hot and cold bulk materials

- Temperature insensitive

- Gentle transport

- Transport over medium to long distances

- High availability

- Low operating costs

- Easy repair

- Low maintenance

In order to be able to process your inquiry more efficiently you will find a questionnaire here through which you can send us the most important information already in advance.

Are you interested in our Vibro conveyors? Or do you have any further questions?

We look forward to your inquiry.

We look forward to your inquiry.